Gears are a critical component in mechanical transmission, playing a vital role in every aspect of industrial production. As the lifeblood of industry, industrial fluids significantly impact gear processing quality, production efficiency, and subsequent performance. Therefore, selecting the appropriate industrial fluid can often have a transformative effect on the gear manufacturing process.

Image

Kerun, a leader in green industrial fluid system solutions for the gear industry. Leveraging strong capabilities in equipment R&D and manufacturing, along with extensive experience in industrial fluid applications, Kerun offers comprehensive gear processing fluids and full lifecycle management services, as well as industrial fluid stewardship services, to help companies improve quality, reduce costs, and increase efficiency.

Gear Processing Workflow

Forging — Rough Turning — Gear Milling, Hobbing, Shaping — Gear Shaving — Heat Treatment — Finish Turning — Internal and External Grinding — Gear Honing — Gear Grinding — Cleaning — Rust Prevention — Hydraulics — Guideways

"

Kerun provides high-performance products for each gear processing step, helping to improve product quality.

Forging Post-forging cooling fluid KR1280

Rough Turning Mineral oil-based metalworking fluid KR-C8510/KR-C8520, fully synthetic metalworking fluid KR-C9020

Gear Milling/Hobbing/Shaping Cutting oil KR-C32/KR-C46, minimal quantity lubrication oil KR-MQL46, mineral oil-based metalworking fluid KR-C8580

Gear Shaving Cutting oil KR-C18/KR-C22L

Heat Treatment Ultra-fast quenching oil KR108, fast bright quenching oil KR218(H), water-soluble quenchants KR6480/KR6580, gear-specific quenching oils KR228C/KR468C/KR498C, isothermal grading quenching oils KR4288/KR4488, vacuum quenching oil KR328

Finish TurningMineral oil-based metalworking fluid KR-C8520/KR-C8560

Internal/External GrindingFully synthetic cutting fluid KR-C9020G, mineral oil-based metalworking fluid KR-C8550/KR-C8510EP

Gear HoningGear honing oil KR-C03N

Gear GrindingGrinding oil KR-C10 /KR-C10L /KR-C10H /KR-C15L /KR-C15H

Cleaning Water-based metal cleaner KR-F400/KR-F400H/KR-F400M, hydrocarbon cleaner KR-CH60/KR-CH90

Rust PreventionWater-based rust inhibitor KR-AOA120/KR-AOA190, thin-layer rust preventive oil KR-A0D330PLUS/KR-A0D350

HydraulicsIndustrial system circulation oil PR EAL-HM32/PR EAL-HM46/PR EAL-HM68

GuidewaysGuideway oil KR-EG68

"

In addition to product services, we also focus on ensuring the full lifecycle operation of projects.

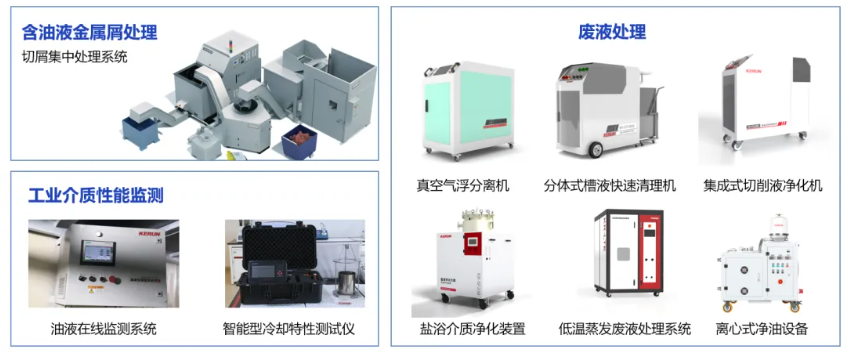

To address the challenges enterprises commonly face, such as the difficult treatment of oily metal chips, waste fluid disposal, and industrial fluid performance monitoring, we provide lifecycle management services for fluids. This helps companies reduce overall operating costs and enhance green production capabilities.

Image | Some of Kerun's Equipment Products

"

Moreover, to meet the complex chemical product requirements and stringent process demands on manufacturing sites, we offer industrial fluid stewardship services.

By tailoring cost-reduction and efficiency-enhancing solutions, we meet customers' pursuit of excellence in quality and effective cost control. At the same time, we bring greater improvements to environmental protection, personnel health, and site management.

If you are still troubled by difficulties in management, frequent quality issues, unreasonable costs, or environmental risks, contact us today! You can directly call your account manager/technical engineer or dial 4008-818-101. You can also leave a message on the Kerun website (www.njkerun.com) or our WeChat official account. We are always by your side.