Today marks the 53rd Earth Day. As a leader in green industrial fluid system solutions, Kerun's commitment to protecting the Earth extends beyond just today. For many years, we have consistently focused on the development and application of green, specialized, and serialized products. By partnering with others, we aim to contribute to the sustainable development of Chinese manufacturing.

Zirconium-Based Green Film Coating Pretreatment Agent

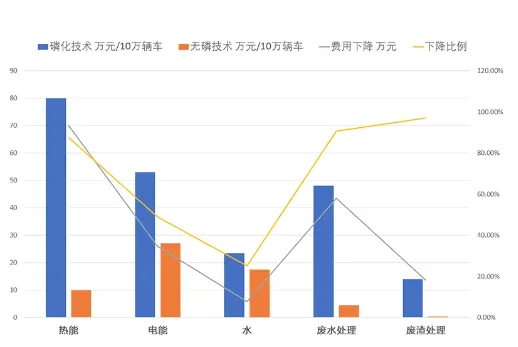

This product uses zirconium-based composite pretreatment technology. Compared to traditional phosphating technology, this innovative approach offers a phosphate-free and nickel-free coating pretreatment. Not only does it deliver excellent performance, but it also boasts significant environmental advantages. By using this product, companies can simplify production processes, improve work efficiency, and reduce harmful environmental emissions, thereby lowering overall operating costs.

Image | Comprehensive Cost Comparison

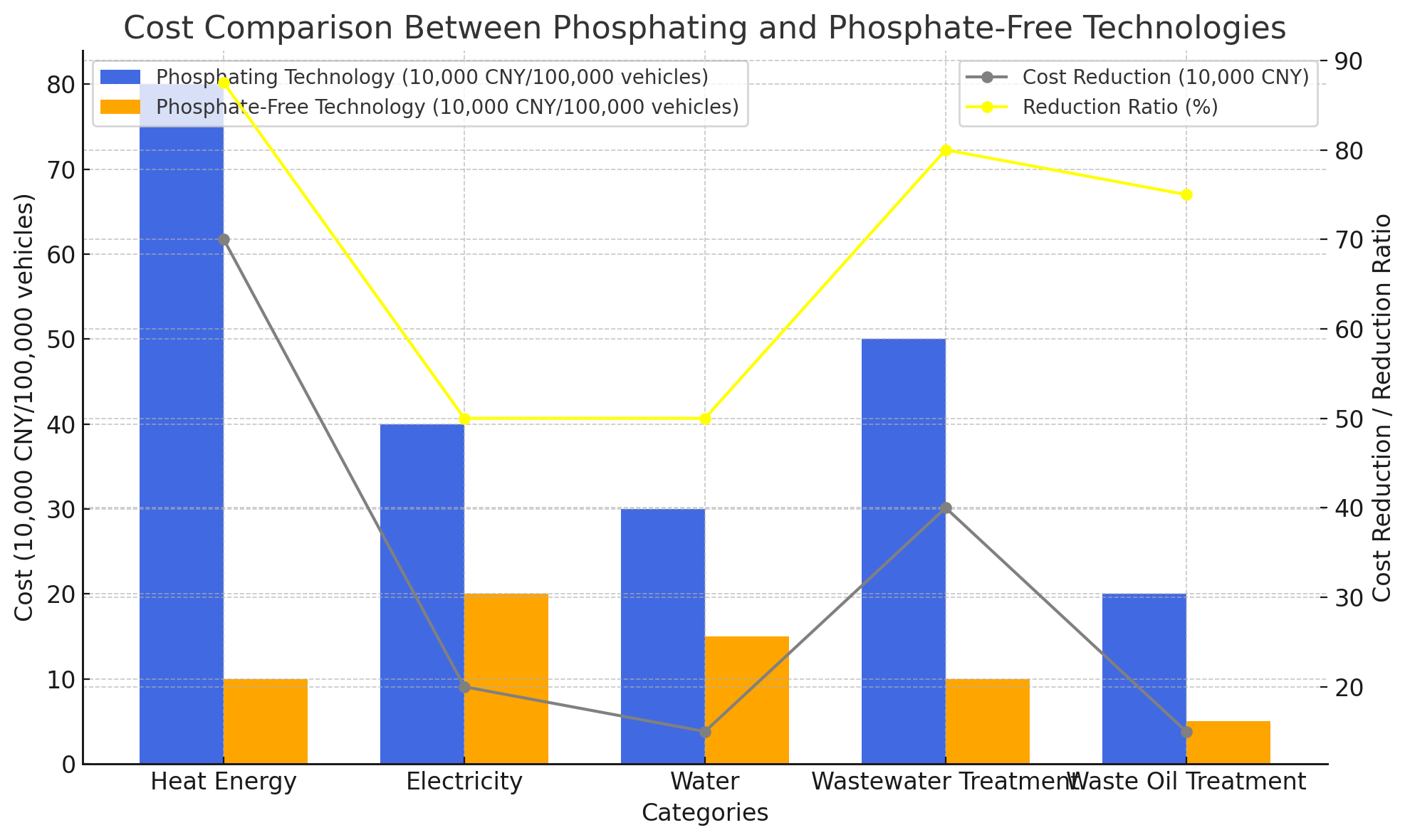

Oil-like Quenching Agent

This product leverages advanced molecular design and key polymer synthesis technologies, enabling the water-based quenching fluid to meet performance standards equivalent to traditional quenching oils. It offers significant advantages in terms of environmental sustainability, cost reduction, and efficiency improvement. By using this product, companies can address issues such as high oil fumes and pollution associated with traditional quenching processes. Additionally, it helps reduce the costs of waste fluid treatment and recovery, resulting in substantial long-term savings for enterprises.

Vegetable Oil Base Metalworking Fluid

This product utilizes advanced plant oil chemical modification technology to synthesize a biodegradable, environmentally friendly plant oil-based modified extreme pressure (EP) additive. This additive replaces traditional mineral oil-based additives in emulsions and semi-synthetic cutting fluids, enhancing the extreme pressure performance of the product while significantly reducing carbon emissions. According to relevant data, each ton of plant oil-based cutting fluid can reduce carbon dioxide emissions by approximately 0.9 to 1.8 tons.

Oil/Fluid Online Monitoring System

Amid the current challenges of labor shortages in the manufacturing sector and the national call for big data transformation, data integration and visualization are becoming key trends for the future development of manufacturing enterprises. This instrument enables real-time online monitoring of fluid performance, assisting customers in achieving on-site visualized, systematic, and data-driven operations management. This approach helps reduce fluid waste and enhances the company's green productivity.

Image | Oil/Fluid Online Monitoring System

Kerun is committed to being a leader in green industrial fluids. In the context of the national "dual carbon" strategy and the accelerating digital transformation of enterprises, we are dedicated to actively assuming social responsibility. We will focus on three key areas: improving quality and efficiency, promoting a circular economy, and ensuring green sustainability. By harnessing advanced fluid technology, we aim to propel high-end manufacturing forward, strive to meet customer needs, and contribute to high-quality societal development.