On June 6, the "Ringier Technology Innovation Awards for the Metalworking Industry" ceremony was grandly held in Shanghai. Nanjing Kerun Industrial Fluids Co., Ltd. (hereinafter referred to as "Kerun") was invited to attend this prestigious event and won the Technology Innovation Award for its water-soluble metalworking fluid, KR-C8930XH.

Image | Kerun Wins the Ringier Technology Innovation Award

This award, organized by Ringier Trade Media Ltd., Asia's leading industrial information media company, aims to recognize innovative products and technologies that have made outstanding contributions to the industry. It is one of the most internationally recognized and professional industrial technology innovation awards in China.

Image | Award Ceremony Scene

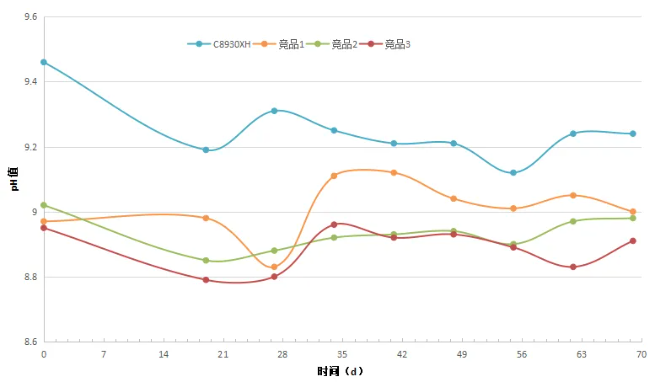

After going through two stages, including online voting by industry users and comprehensive evaluation by industry experts, Kerun's KR-C8930XH stood out as a technologically innovative, high-performance, and widely applicable biostable metalworking fluid. When combined with full lifecycle management measures and integrated purification equipment, it can extend the fluid's lifespan by 30-50%.

Image | KR-C8930XH Metalworking Fluid

About the Award-Winning Product KR-C8930XH

“

Development Background

Traditional cutting fluids often contain extreme pressure agents like sulfur, chlorine, and phosphorus, as well as biocides like boron and formaldehyde. These additives can lead to severe environmental pollution and occupational health hazards during use and waste disposal. Additionally, treating waste fluids requires significant energy and resources. As a result, developing environmentally friendly, long-lasting, and recyclable cutting fluids has become a research focus.

“

Product Advantages

1.Boron-Free, Formaldehyde-Free Long-Lasting Antimicrobial Technology

By studying various factors affecting the lifespan of cutting fluids, including alkalinity retention, types of biocides, and the combination of antimicrobial systems, we identified key factors. Through the optimized combination of these factors, we developed a long-lasting antimicrobial technology free of boron and formaldehyde, distinct from traditional antimicrobial techniques.

2.Wide Applicability

This fluid is particularly suitable for common conditions in aerospace aluminum alloy, titanium alloy, and automotive core component processing. It is applicable in both single-machine and centralized supply systems, helping clients reduce the variety of fluids needed and simplifying on-site chemical management.

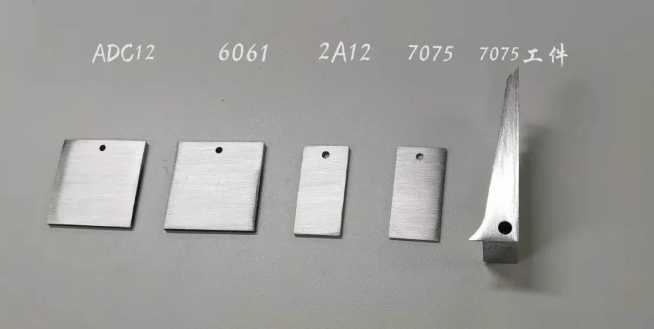

Image | Aerospace Workpiece Surface Shining Like New

Image | Corrosion Inhibition Effect on Various Aluminum Alloys

3.High Safety

KR-C8930XH is free from harmful substances such as boron, triazine, nitrites, organic phenols, chlorinated paraffins, diethanolamine, formaldehyde-releasing biocides, and heavy metals, thereby reducing the impact on operators and the environment.

4.High Stability

The product features a specially designed formula that ensures excellent performance stability, biological stability, and emulsion stability. It maintains stable processing performance even under long-term, high-speed cutting conditions, keeps the machine's internal surfaces clean, and has a long service life, reducing waste fluid discharge.

Image | Comparison of Microbial Challenge Test Results

Application Case

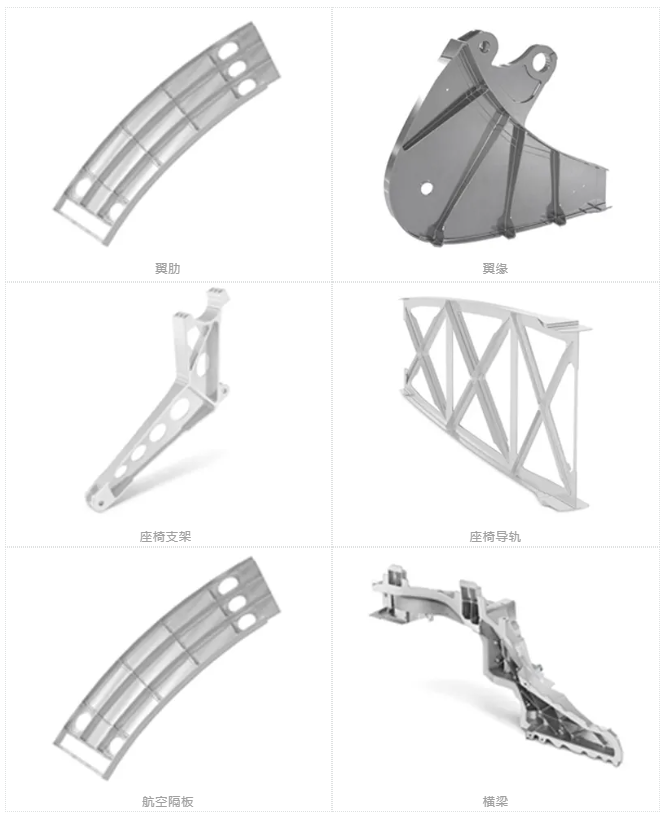

A domestic aerospace component manufacturer, dedicated to the design and production of military aviation CNC parts, such as wing ribs, seat frames, aviation partitions, and beams, has been using the KR-C89XH series products. Since then, they have improved the production environment, extended the fluid's lifespan, reduced overall operational costs, and accelerated the localization process.

……

Kerun is committed to becoming a leader in green industrial fluids. In the future, Kerun will continue to adhere to the development philosophy of "technology-driven value," focusing on the research, production, and application of green industrial fluids to support the advancement of high-end manufacturing.