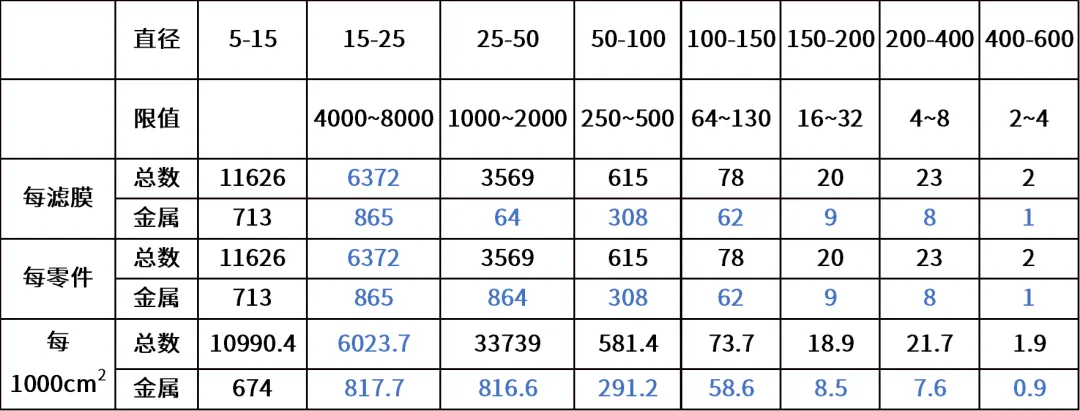

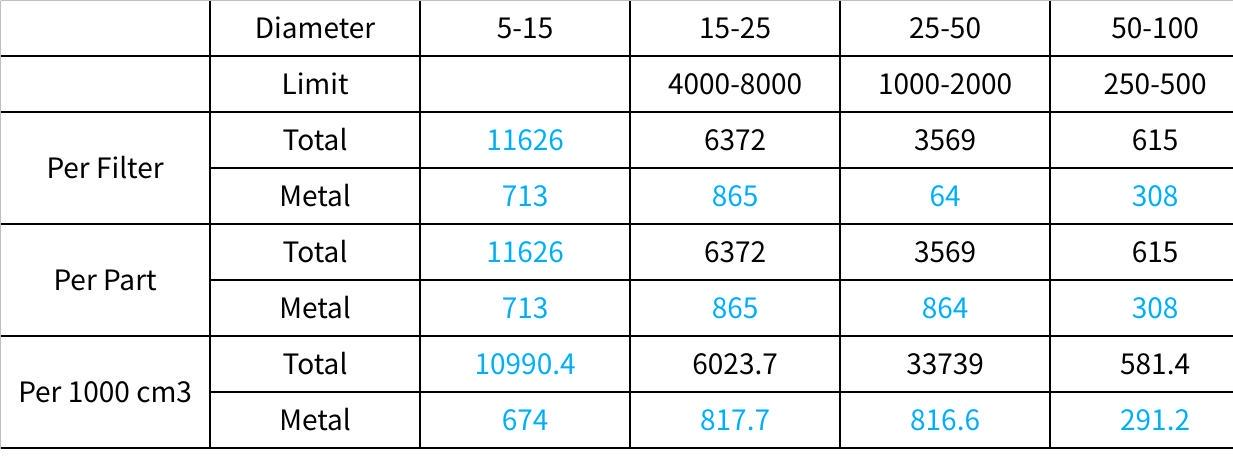

For different application

The standard of workpiece cleaningnes is different

Therefore, to meet different process requirements,

when selecting a cleaning agent,

one should comprehensively consider factors such as

the cleaning method, type of cleaning agent, cleaning performance, and the cleaning equipment used.

Cleaning Method

Common cleaning methods include manual wiping, soaking, ultrasonic cleaning, and various pressure spraying techniques. For small parts, a combination of spraying, ultrasonic cleaning, and soaking can be used. For medium and large workpieces, soaking and ultrasonic cleaning are suitable methods.

Type of Cleaning Agent

Common types of cleaning agent include water-based, solvent-based, acids and alkalis. The appropriate cleaning agent should be selected based on the material to be cleaned, ensuring that it effectively removes surface fluids, oil, metal oxides, or rust from the workpiece.

Cleaning Performance

After recommending the appropriate type of cleaning agent based on the contaminants like oil, oxides, metal chips, and rust on the workpiece surface, it’s important to consider the on-site equipment. The selected cleaner should meet various requirements, such as cleaning ability, foam control, and odor.

Cleaning Equipment

The quality and configuration of cleaning equipment can directly affect the cleanliness of the workpieces. The equipment must offer high cleaning efficiency and have a comprehensive filtration system. During the commissioning of new machines, it is essential to ensure that the workpieces meet cleanliness standards after cleaning. Additionally, the equipment should comply with relevant national and industry standards.

As a leader in green industrial fluid solutions,

We use our strong expertise to offer scientifically sound cleaning solutions.

Helping reduce particle wear and increase system reliability and lifespan.

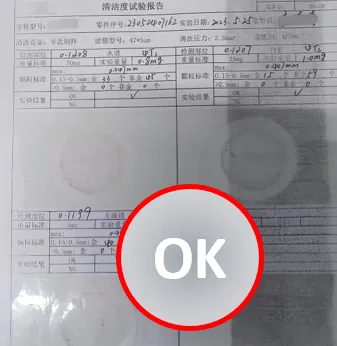

Case 1

Differential Assembly

Cleaning Process: Pre-set Station - 30kg High-Pressure Spraying - 40MHz Ultrasonic Cleaning - Simple Air Blow Drying - 40MHz Ultrasonic Rinsing - Spraying Rinse - Compressed Air Blow Drying - Drying - Vacuum Drying - Cold Air Cooling

Suggested Poduct

Aqueous Metal Cleaning Agent KR-F500

Cleanliness Inspection Result: Pass

Different cleaning methods were set up on-site to test cleanliness, and our products met all cleanliness requirements.

Case 2

Transmission Gear

Case 2:#1 Spraying Cleaning-#2 Spraying Cleaning-#3 Ultrasonic Cleaning-4#Rust Prevention Tank-5#Rust Prevention Tank-1#Vacuum Drying-2#Vacuum Drying

Suggested Product

Aqueous Metal Cleaning Agent KR-F400M

Cleanliness Inspection Result: Pass

After continuous use of the cleaning agent for several days, the product's performance remained stable and consistently met the customer's cleanliness requirements.

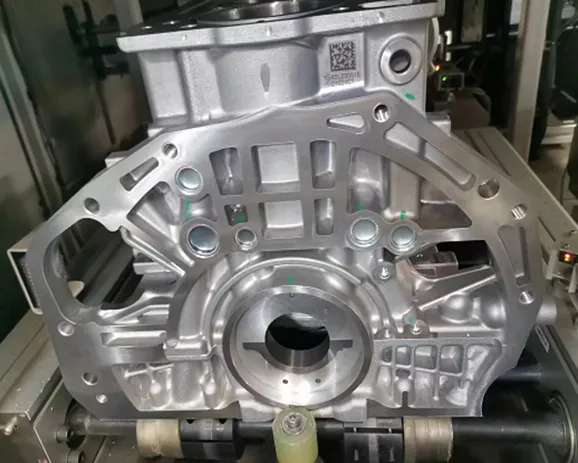

Case 3

Automotive Engine Assembly

Cylinder Block Final Cleaning Machine Process Line:

Pre-Cleaning Machine:Single-position, single-tank spray cleaning with a 2300L liquid tank, steel mesh filter/filter bag (50-100μm), temperature 40-60°C, cleaning duration approximately 2 minutes.

Final Cleaning Machine: Spraying Cleaning ≤1.2MPa→Spraying Rinse ≤1.2MPa→Main Oil Passage High-Pressure Rinse ~20MPa→Air Knife Drying→External Vacuum Drying;Cleaning temperature 40-60°C, actual display 50°C.

Cleaning Fluid:MWF,Hoing fluid.

Suggested Product

Aqueous Metal Cleaning Agent KR-V300

Cleanliness Inspection Result: Pass

After cleaning workpiece,cleanliness inspection result is very stable.