In recent years, amid the national drive to accelerate new productivity development, heat treatment has become an indispensable and crucial process in mechanical manufacturing, making its green transformation and sustainable development increasingly important.

As a key element in the heat treatment process, the management and optimization of the full lifecycle of industrial fluids play a vital role. This not only impacts production efficiency and cost control for enterprises but also serves as a crucial factor in enhancing their green competitiveness.

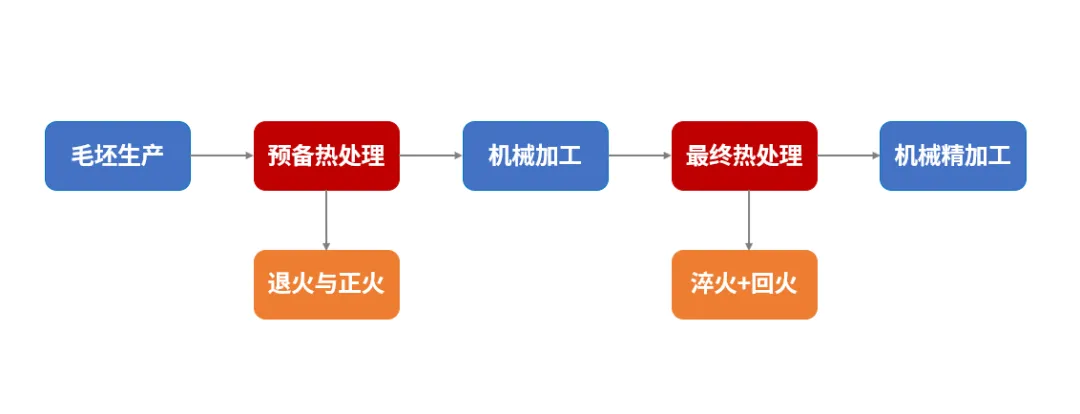

Image | Typical Production Process Route for General Parts

Kerun is committed to becoming a leader in green industrial fluids. Since its establishment in 2000, Kerun has been deeply involved in the heat treatment industry for many years. Upholding the business philosophy of "technology-driven value," and leveraging our strong capabilities in instrument and equipment research, manufacturing, and extensive experience in industrial fluid applications, we have developed a comprehensive range of thermal processing products. We provide our partners with specialized, green and systematic solutions.

Part 1

Developing a Comprehensive Thermal Processing Product Line

We collect on-site data, analyze process workflows, and assess the condition of production equipment to help our customers develop and implement tailored product solutions for various complex operating conditions. These efforts are aimed at enhancing our customers' production efficiency.

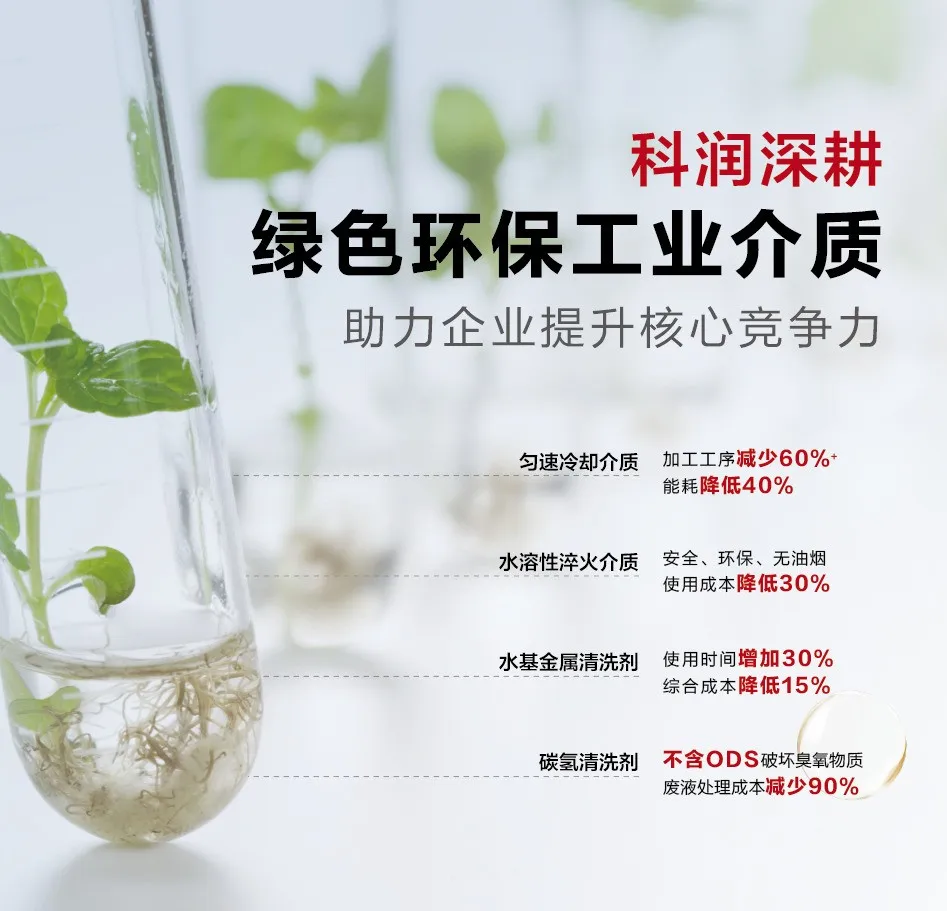

Kerun's Commitment to Green and Environmentally Friendly Industrial Fluids

Empowering Companies to Enhance Core Competitiveness

Uniform Cooling Fluid

- Reduces processing steps by over 60% - Lowers energy consumption by 40%

Water-Based Quenching Fluids

- Safe, environmentally friendly, oil-free - Reduces usage costs by 30%

Aqueous Metal Cleaners

- Increases usage time by 30% - Lowers overall costs by 15%

Hydron Carbon Cleaners

- Free of ODS (Ozone-Depleting Substances) that damage the ozone layer

- Reduces waste treatment costs by 90%

Currently, we have developed a comprehensive thermal processing product line, which includes quenching oils, water-soluble quenching agents, oil-like quenching agents, salt bath quenching media, cleaners, rust inhibitors, blackening agents, and anti-carburizing coatings. This diverse product line is designed to meet the varied needs of our customers.

|

|

|

|

|

Image | Part of heat treatment industry products

Part 2

Providing Efficient Fluid Support Equipment

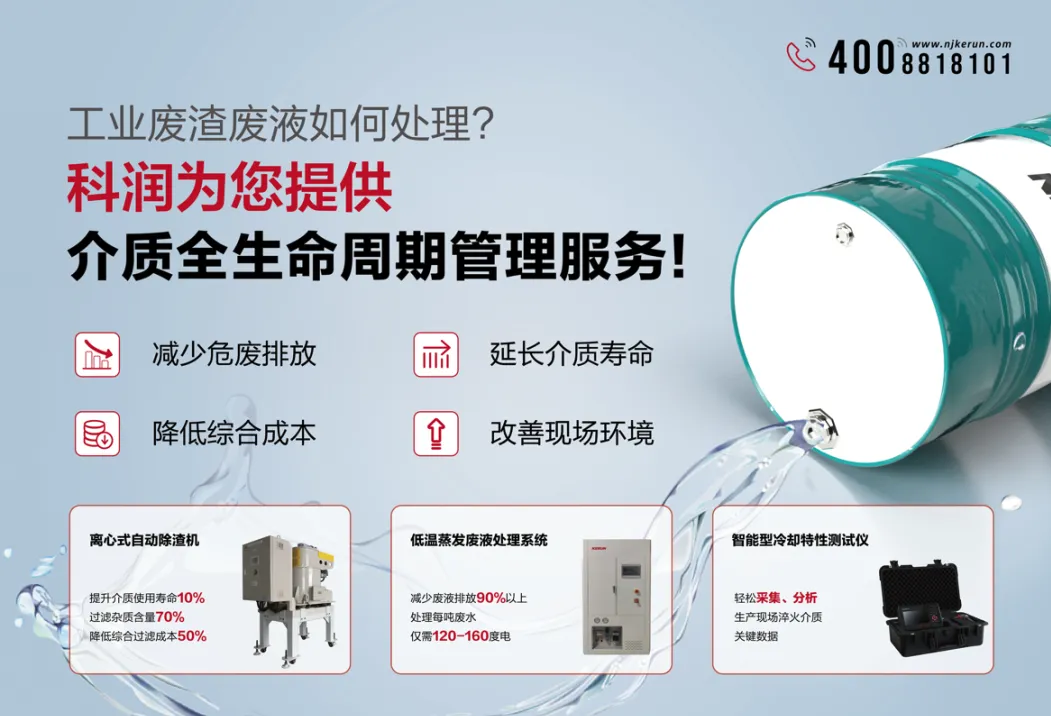

In addition to supplying environmentally friendly industrial fluids at the source, we also enhance the sustainability of our customers' heat treatment production processes throughout the entire lifecycle by offering complementary fluid support equipment.

How to Handle Industrial Waste Fluids?

Kerun Provides You with Comprehensive Lifecycle Management Services for Fluids!

Centrifugal Automatic Sludge Separator

Low-Temperature Evaporation Waste Fluid Treatment System

Smart Quenchant Tester

For example, with the Oil/Fluid Online Monitoring System, data integration and visualization have become key trends in the future development of manufacturing enterprises, especially given the current challenges in labor recruitment and the national push for big data transformation. This system enables real-time online monitoring of fluid performance, helping customers achieve on-site visualized, systematic, and data-driven operations management.

Image | KR-QL Oil/Fluid Online Monitoring System

KR-QL Oil Fluid Online Monitoring System - Quenching Live

Product Information:

Quenching oil undergoes continuous intense thermal shocks during service, leading to thermal aging, oxidation, and polymerization reactions. These changes deteriorate the cooling performance of the quenching oil. At the same time, the oil is subjected to contamination from external impurities like soot, dust, and oxides, which further degrade its quality, causing fluctuations in its properties and even quenching process failures.

The Quenching Live oil fluid online monitoring system is specifically developed to meet the need for real-time quenching oil monitoring. The KR-QL system offers visual, systematic, and data-driven management, enabling real-time on-site oil monitoring. It assists technical staff in maintaining operation plans, improves user confidence in oil usage, reduces operating costs, and enhances product processing quality.

Advantages:

- Fully Meets Project Requirements

- Reliable, Accurate Results

- Easy Installation and Maintenance

- Customizable for Various Needs

Over the years, by providing high-quality products and attentive service throughout the full lifecycle of heat treatment, we have not only earned high recognition from our industry clients but have also received numerous honors. These include the Quality Integrity Enterprise Award in the Heat Treatment Industry, the Green Manufacturing Science and Technology Progress Award, the Aerospace Center Recommended Product designation, and the User Satisfaction Brand award.