Project Background:

A U.S.-based automotive parts supplier, one of the largest globally, is committed to providing innovative and sustainable mobility solutions to the automotive market, including emissions, thermal management, turbocharging systems, Morse systems, drivetrain systems, and power drive systems.

Challenge:

At the early stage of establishing their plant in China, the customer opted for imported quenching and anti-rust oils. However, over time, issues arose with these oils, including difficulty in cleaning, non-compliance with environmental standards, and high usage costs. To enhance long-term operational efficiency, the customer sought a new supplier of high-quality oils that could maintain product quality and production efficiency while reducing costs and boosting sustainable production.

Solution:

To address these complex challenges, Kerun formed an expert team and conducted multiple trials. Based on the results, we recommended KR218H Fast Bright Quenching Oil and KR-AOD350 Thin-Film Rust Preventative Oil:

· KR218H Fast Bright Quenching Oil offers high cooling speed and stability, with strong hardening capabilities that ensure optimal performance of workpieces. Its relatively low viscosity allows for easier cleaning during production, significantly reducing waste liquid discharge.

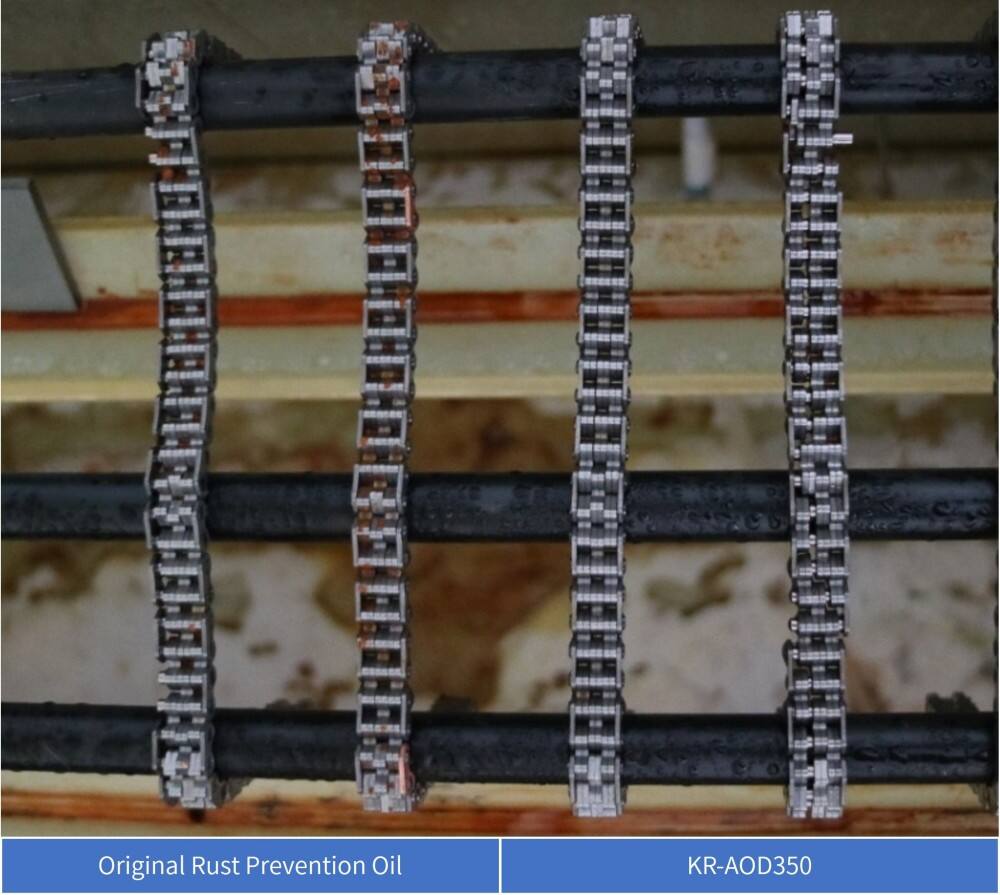

· KR-AOD350 Thin-Film Rust Preventative Oil is highly versatile, featuring a light oil film, low viscosity, excellent flow properties, and high cleanliness. It meets complex processing requirements while minimizing waste and extending usage cycles.

Benefit:

This solution enabled the customer to achieve stable quality and cost-saving goals.

· KR218H High-Speed Bright Quenching Oil has been in stable use for seven years, meeting quality requirements for various parts while reducing overall oil costs by over 30%.

· KR-AOD350 Rust Preventative Oil has been in use for six years without any rust issues, significantly improving both oil quality and performance compared to previous products.

Related Products:

KR218H、KR-AOD350