Project Background:

A precision machining company in Wuxi, recognized as a high-tech enterprise in Jiangsu Province and one of the leading manufacturers of turbocharger components in China, specializes in producing automotive parts, engine blocks, aircraft seat brackets, and automotive turbochargers.

Image | Engine Block Illustration

Customer's Difficulties:

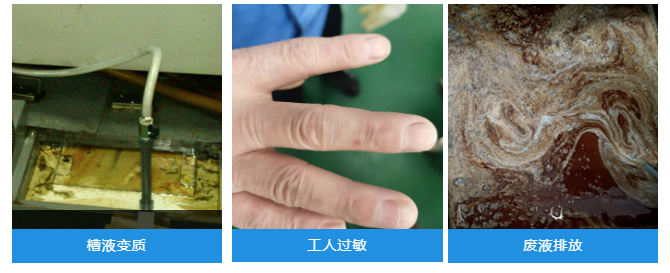

The client frequently encountered oil leakage issues from their machines on the production floor. Combined with the staff's limited awareness of cutting fluid maintenance, this often resulted in water and impurities mixing into the cutting fluid, leading to fluid degradation and widespread worker allergies. Additionally, aluminum corrosion on workpieces during production was a recurring problem. As a result, the client had to frequently replace the cutting fluid to maintain the quality of the workpieces. This not only significantly reduced production efficiency and increased operational costs but also posed a considerable burden in terms of waste fluid disposal.

Total Solution:

To address these issues, we engaged in thorough communication with the client and, based on their stringent performance requirements, conducted product analysis and development, ultimately formulating the following solutions:

1.Customized Cutting Fluid Formulation for Green Production

We customized KR-C8020AF, a cutting fluid tailored to the client's specific needs, ensuring high-precision machining with center hole accuracy of 0.1 µm, 30,000 RPM speeds, and easy cleaning of electroplated impellers. This improved the on-site processing environment and met the client's green production requirements.

2.Focus on Biocide Issues to Reduce Worker Allergy Risks

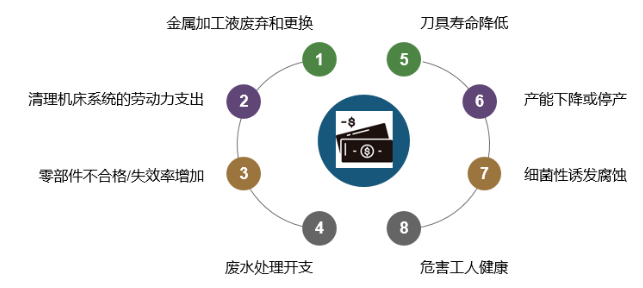

Microbial growth is the root cause of metalworking fluid degradation. Therefore, prevention is crucial. Before changing the cutting fluid, it is essential to thoroughly clean and disinfect each machine’s fluid tank. Regular maintenance of the fluid is also recommended, with close monitoring of concentration, pH levels, appearance, and odor.

Image | Losses Caused by Microbial Growth in Metalworking Fluid

3.Utilizing a Centralized Supply System to Reduce Waste Fluid Disposal

To improve the effective use of cutting fluids, we recommended using a centralized supply system, which efficiently controls the fluid concentration and reduces waste fluid disposal. Over a year, the client’s single-machine supply system consumed 132 large barrels of cutting fluid. By switching to a centralized supply system and recycling compressed fluid, the annual consumption was reduced to 100.8 barrels, saving 23.64% in cutting fluid usage.

Image | Annual Consumption of Centralized Supply System

Customer Feedback:

After using our cutting fluid for some time, the client reported that the production site had a mild and non-irritating odor, the fluid's lifespan significantly improved, and waste fluid disposal was no longer an issue. Additionally, Kerun's professional and timely technical services provided the client with great peace of mind.

Kerun is committed to being a leader in green industrial fluids, using cutting-edge technology to support advanced manufacturing.