Onsite Requirement

A core subsidiary of a leading domestic steel group is renowned in the domestic bright steel sheet market for its exceptional shape and thickness accuracy control, as well as impeccable surface quality. Its products are widely used in various fields, including automotive, high-end home appliances, and kitchenware.

The company has been using a phosphorus-containing degreaser from a foreign brand in its bright sheet degreasing process. However, with the rapid development of new energy vehicles and the accelerating pace of domestic substitution, the company is now facing the following challenges:

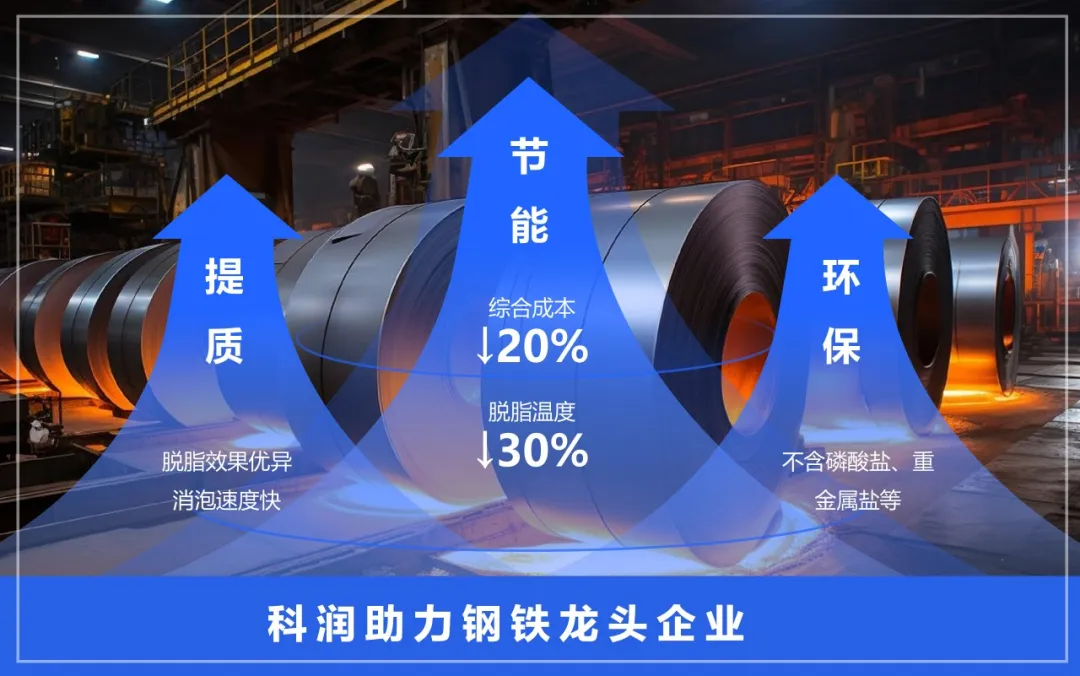

In response to these challenges, Kerun's R&D team custom-developed the KR-RSD series of phosphorus-free degreasers, meeting the high standards required for bright sheet cleaning. This solution successfully reduced overall costs and degreasing temperatures, achieving the triple goals of energy saving, quality improvement, and environmental protection.

After thorough testing and validation, the KR-RSD series demonstrated excellent performance on the production line, helping the client advance towards enhanced quality, improved efficiency, reduced energy consumption, and green, sustainable development.

01

Great performance

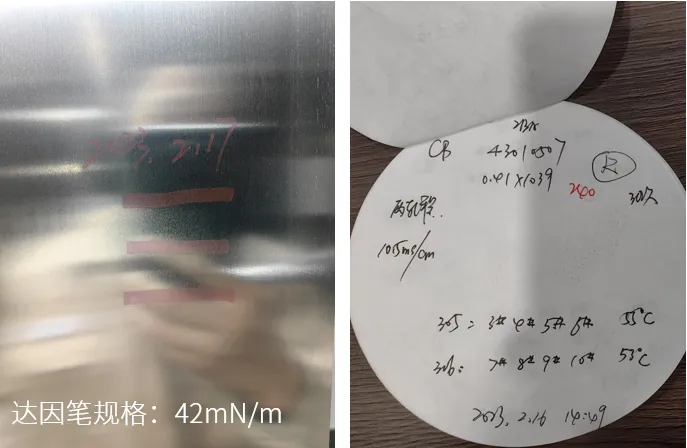

Strong oil removal capabilities, fast degreasing speed, and excellent de-graying effects.

Image | Degreasing Effect Verification Results

Operating temperature is low(50-55℃),Excellent Defoaming Property。

Image | Foam Effect Comparison Before and After

02

Energy Save

After implementing the KR-RSD series, the alkaline wash stage temperature setting was reduced by 30%, and the corresponding steam valve opening of the heat exchanger was decreased by 50%. Overall calculations showed that the company's annual comprehensive usage costs were reduced by more than 20%.

03

Safty&Eco-friendly

The degreaser is free of phosphates, silicates, borates, and heavy metal salts, all of which are harmful to the environment, thereby reducing environmental pollution.

The State Council's recent release of the "Action Plan to Promote Large-Scale Equipment Upgrades and the Replacement of Old Consumer Goods" has created unprecedented opportunities for the automotive and home appliance industries, potentially driving a massive market worth over 5 trillion yuan annually. This policy not only accelerates the renewal of consumer goods but also injects new vitality into the upstream stainless steel market, fostering further optimization of product structures.

As a provider of green industrial fluids, Kerun will continue to invest in research and development, offering steel industry customers green, systematic fluid solutions across various processes, including hot rolling, cold rolling, leveling, degreasing, and rust prevention.