Your Trusted Expert in the Heat Treatment Industry

In heat treatment processes, the importance of quenching medium lies in its decisive impact on the final performance and quality of the workpiece. Since Kerun successfully developed its first quenching oil in 2000, we have continuously expanded our product portfolio to include quenching oils, polymer quenchants, salt bath quenchants, and anti-carburizing coatings. Today, Kerun proudly serves clients across diverse industries such as aerospace, automotive, and wind energy. We offer tailored heat treatment solutions based on the unique characteristics of each customer’s products, ensuring excellent performance and stable, controllable quality.

As a global leader in the heat treatment industry, Kerun is committed to driving innovation in process technology. Beyond product support, we emphasize the entire lifecycle of industrial fluids and provide a comprehensive suite of services including process simulation, quenching medium selection and customization, on-site precision management, and advanced technical support and training. These offerings are designed to help our heat treatment clients enhance their core competitiveness.

Process Optimization

At Kerun, our team of technical engineers and industry experts collaborates closely with clients to select the optimal quenching medium for various applications, achieving the following objectives:

• Meet required material performance

• Enhance operational efficiency

• Reduce overall costs

• Promote sustainable, green production

-

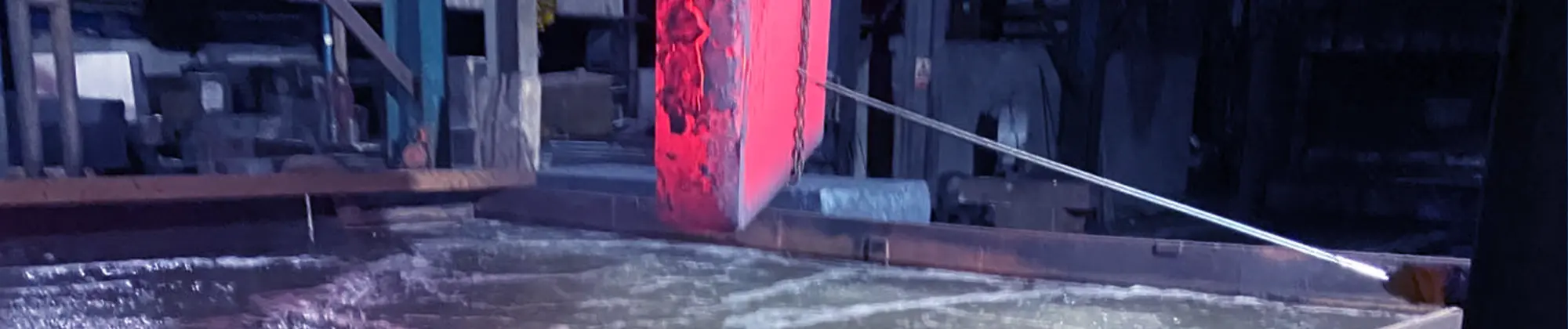

Quenching Oil

Quenching oil is a mineral oil-based cooling medium that, through the combination of base oils and additives, provides the cooling properties needed for ferrous metal quenching. It features excellent oxidation stability, long service life, and minimal deformation, making it suitable for various mechanical parts.

-

Polymer Quenchant

Polymer Quenchants are water-soluble solutions made from high molecular weight polymers with multiple functional additives. They offer controllable cooling performance and high environmental efficiency, ideal for heat treatment quenching of mechanical parts with strict environmental requirements.

-

Molten Salt Quenchant

Salt bath quenchant are formed from inorganic salts in different ratios, with relatively low melting points. Through process control, they achieve controllable cooling performance and enable martensitic or bainitic quenching. They effectively reduce workpiece deformation, suitable for martensitic graded quenching or bainitic isothermal quenching parts requiring high precision.

-

Blackening Agent

Blackening agent is a chemical used for metal surface treatment, primarily to form a black oxide layer on the metal surface. This process aims to provide rust and corrosion resistance as well as decorative effects, and it is applied to the surface treatment of various metal products.

-

Anti-Carburizing Coating

Anti-carburizing coatings are protective coatings designed to prevent carbon penetration in specific areas during metal heat treatment. They offer fast drying, resistance to peeling, environmental safety, and ease of application, making them suitable for large-scale or localized anti-carburizing treatments.

Class Example

Saving More Than 30% Overall Cost

Kerun supports a globally renowned automotive parts company in enhancing overall efficiency

Learn More