Advocate for Vegetable Oil Based Cutting Technology

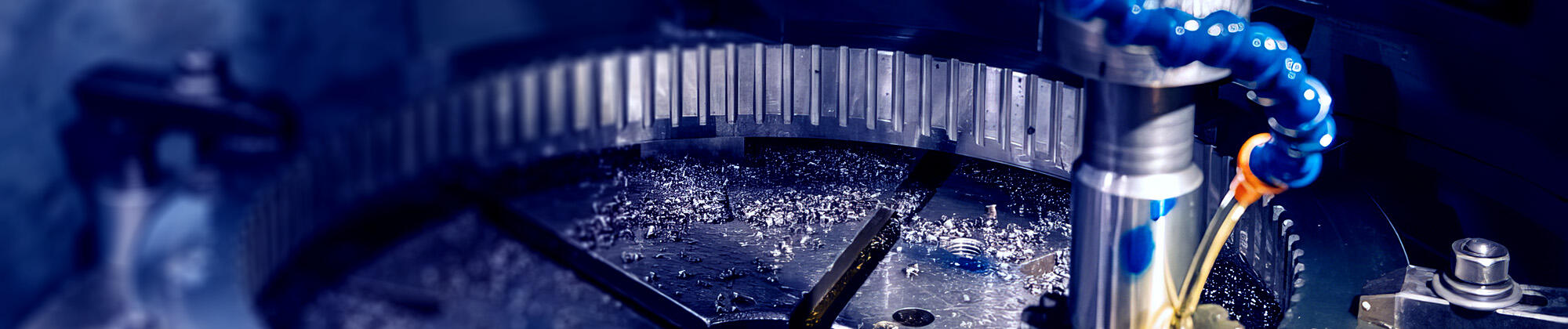

As a leading brand in the metalworking fluids industry, Kerun is dedicated to the development and application of innovative, eco-friendly metalworking fluids. One of our key achievements has been pioneering vegetable oil based cutting technology. Kerun’s vegetable oil based metalworking fluids, developed with this technology, offer excellent lubricating performance and biodegradability. They maintain high machining quality and a lifespan comparable to traditional mineral oil-based cutting fluids.

Supported by such advanced technology, our comprehensive line of metalworking fluids is widely used across various industries, including automotive, aerospace, and construction machinery. These products enable our clients to ensure stable product performance, reduce costs, minimize environmental impact, protect occupational health, and enhance production efficiency.

Process Optimization

Metalworking fluids are essential to the machining process, addressing key challenges in metalworking with the following advantages:

• Extending tool life

• Enhancing workpiece surface finish

• Providing rust prevention for equipment and workpieces

• Reducing environmental impact

-

Cutting Fluid

Cutting fluid is primarily based on mineral oil or synthetic oil (fully synthetic cutting fluids do not contain base oil) and is formulated with various powerful additives such as coolants, lubricants, and rust inhibitors. It emphasizes cooling and lubrication effects and is widely used in metal cutting and grinding operations.

-

Cutting Oil

Cutting oil is a specialized fluid or lubricant used in metalworking and machining processes. It forms a lubricating film between the tool and the workpiece, reducing friction and wear, thereby improving machining accuracy and efficiency. It is widely used in various metalworking fields.

-

Grinding Oil

Grinding oil generally uses mineral oil or synthetic oil as a base, with additives like extreme pressure additives, anti-wear agents, and antioxidants. It provides excellent lubrication and corrosion resistance, making it ideal for grinding operations that require high precision and superior surface quality.

-

Honing Oil

Honing oil is based on deeply refined mineral oil and blended with high-performance imported additives. It is specifically designed for honing processes, offering efficient lubrication and cooling, especially suitable for machining high-precision parts.

-

Minimal Quantity Lubricant

Minimal quantity lubricant is a type of lubricant produced using Micro Lubrication Technology (MQL). It features environmental friendliness, high energy efficiency, and ease of operation. It is suitable for various metalworking applications, especially high-speed machining of non-ferrous and ferrous metals.

Class Example

Meet Stability and Cost Control Needs

PProviding industrial fluid system solutions to meet the wind power industry's demands for quality stability and cost control.

Learn More