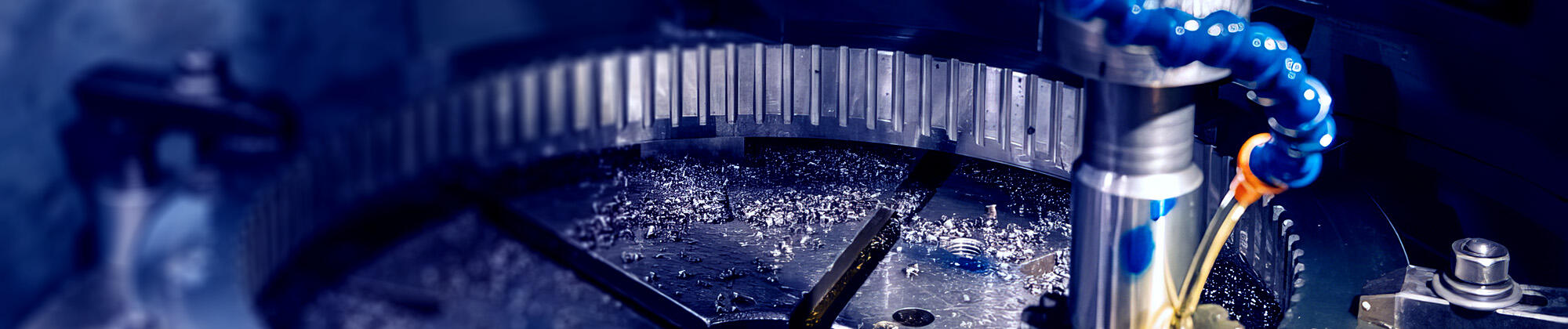

Cutting Fluid

Cutting fluid is primarily based on mineral oil or synthetic oil (fully synthetic cutting fluids do not contain base oil) and is formulated with various powerful additives such as coolants, lubricants, and rust inhibitors. It emphasizes cooling and lubrication effects and is widely used in metal cutting and grinding operations.

-

KR-C8210

The mineral oil based metalworking fluid is formulated with new environmentally friendly additives, offering excellent lubrication, anti-rust, cleaning, aluminum protection, and microbial stability. It is safe and environmentally friendly.

Learn More -

KR-C8023

The mineral oil-based metalworking fluid is formulated with new environmentally friendly additives, providing excellent lubrication, rust prevention, cleaning, aluminum protection, and microbial stability. It is both safe and eco-friendly, making it suitable for various metal processing applications.

Learn More -

KR-C8790

The mineral oil-based metalworking fluid is a water-soluble, high-performance solution specifically designed for magnesium alloy processing. It offers excellent lubrication, cooling, cleaning, and rust prevention properties, effectively preventing hydrogen release and discoloration issues during magnesium alloy machining. This fluid is safe and environmentally friendly, making it ideal for demanding applications.

Learn More -

KR-C8026

The mineral oil-based metalworking fluid is a water-soluble solution designed for metal processing. It provides excellent corrosion inhibition for non-ferrous metals, along with superior lubrication, cooling, cleaning, and rust prevention properties, making it highly effective for various metalworking applications.

Learn More -

KR-C8030

The mineral oil-based metalworking fluid is formulated with special lubricating additives, offering excellent lubrication, cleaning, and aluminum protection properties. It also features outstanding biological stability, making it highly suitable for demanding metalworking applications.

Learn More