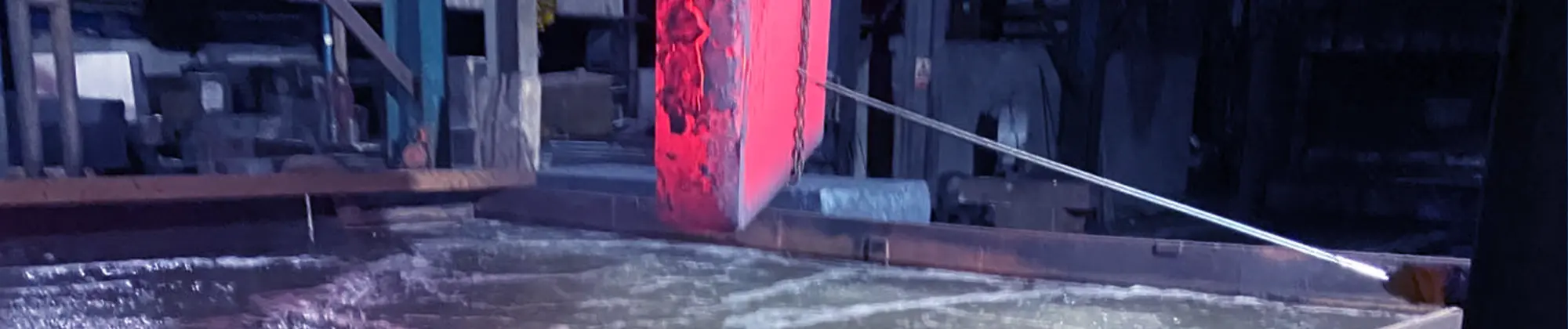

Heat Treatment

At Kerun, our R&D engineers and industry experts collaborate closely with our customers to determine the most suitable quenching medium according to different application requirements.

-

KR498

Quenching deformation is one of the three primary challenges in heat treatment quality control. KR498 Isothermal Graded Quenching Oil effectively reduces quenching deformation in thin-walled, complex-shaped workpieces such as automotive gears, motorcycle gears, clutch plates, and bearing rings. This results in improved product precision, reduced machining allowance, and significantly lower production costs.

Learn More -

KR4188

Quenching deformation is one of the three primary challenges in heat treatment quality control. KR4188 Isothermal Graded Quenching Oil effectively reduces quenching deformation in thin-walled, complex-shaped workpieces such as automotive gears, motorcycle gears, clutch plates, and bearing rings. This results in improved product precision, reduced machining allowance, and significantly lower production costs.

Learn More -

KR098

Insufficient hardness in high-chromium steel balls is a common issue with air quenching. Increasing alloy content raises production costs and often has limited effectiveness. In response, many wear-resistant manufacturers are considering quenching oil instead. KR098 Quenching Oil, specifically tailored for the steel ball industry, significantly enhances the quenching hardness of high-chromium steel balls. It addresses issues such as inadequate hardness and poor impact toughness associated with air quenching, while also reducing production costs and enhancing market competitiveness for enterprises.

Learn More -

KR535

For parts requiring high surface brightness and uniform hardness, using KR535 Tempering Oil instead of a conventional air furnace yields superior results. This specialized oil ensures enhanced surface quality and consistent hardness throughout the workpiece, meeting stringent quality demands.

Learn More -

KR1280

This water-soluble, uniform cooling medium, which is non-reverse-soluble, exhibits very slow cooling performance at higher concentrations. Due to the absence of reverse solubility, the medium's cooling speed can be controlled by adjusting its operating temperature, thus enhancing its versatility across various applications.

Learn More -

KR8180

This water-soluble, uniform cooling medium, which is non-reverse-soluble, exhibits very slow cooling performance at higher concentrations. Due to the absence of reverse solubility, the medium's cooling speed can be controlled by adjusting its operating temperature, thus enhancing its versatility across various applications.

Learn More -

KR6480

It effectively improves the heat treatment work environment and enhances the quenching quality of parts.

Learn More -

KR7280

This advanced, environmentally friendly, water-soluble quenching agent provides faster cooling rates at high and medium temperatures compared to tap water, significantly enhancing the hardened layer depth of quenched workpieces.

Learn More