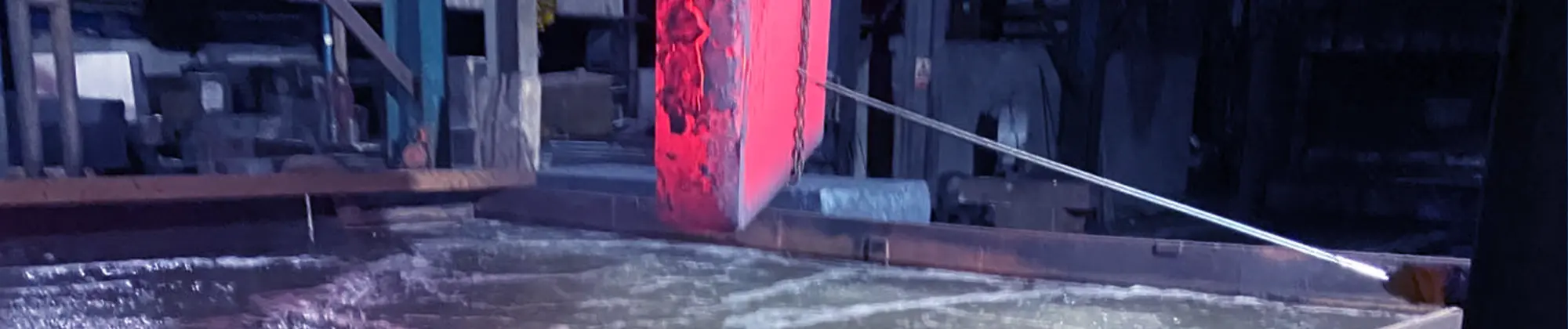

Quenching Oil

Quenching oil is a mineral oil-based liquid medium with strong cooling performance and excellent oxidation stability, suitable for small parts that require rapid cooling and are sensitive to deformation.

-

KR498

Quenching deformation is one of the three primary challenges in heat treatment quality control. KR498 Isothermal Graded Quenching Oil effectively reduces quenching deformation in thin-walled, complex-shaped workpieces such as automotive gears, motorcycle gears, clutch plates, and bearing rings. This results in improved product precision, reduced machining allowance, and significantly lower production costs.

Learn More -

KR4188

Quenching deformation is one of the three primary challenges in heat treatment quality control. KR4188 Isothermal Graded Quenching Oil effectively reduces quenching deformation in thin-walled, complex-shaped workpieces such as automotive gears, motorcycle gears, clutch plates, and bearing rings. This results in improved product precision, reduced machining allowance, and significantly lower production costs.

Learn More -

KR098

Insufficient hardness in high-chromium steel balls is a common issue with air quenching. Increasing alloy content raises production costs and often has limited effectiveness. In response, many wear-resistant manufacturers are considering quenching oil instead. KR098 Quenching Oil, specifically tailored for the steel ball industry, significantly enhances the quenching hardness of high-chromium steel balls. It addresses issues such as inadequate hardness and poor impact toughness associated with air quenching, while also reducing production costs and enhancing market competitiveness for enterprises.

Learn More -

KR535

For parts requiring high surface brightness and uniform hardness, using KR535 Tempering Oil instead of a conventional air furnace yields superior results. This specialized oil ensures enhanced surface quality and consistent hardness throughout the workpiece, meeting stringent quality demands.

Learn More